PRODUCT LIFECYCLE MANAGEMENT

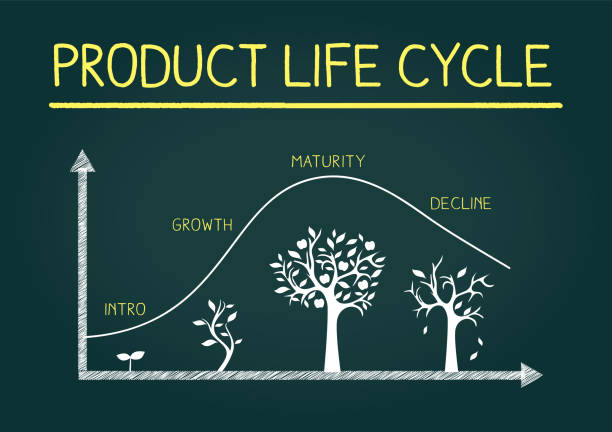

Product Lifecycle Management (PLM) is a process that manages the entire lifecycle of a product from conception to retirement. PLM involves the coordination of people, data, processes, and business systems to ensure that the right product is delivered to the market at the right time. It includes activities such as ideation, design, development, manufacturing, distribution, and end-of-life management. PLM enables companies to make informed decisions throughout the product lifecycle, improve collaboration, reduce costs, and accelerate time-to-market.

Build your Ideal Product Roadmap

From product strategy to launch, manage it all with one flexible platform

Product Lifecycle Management (PLM) is a comprehensive approach to managing the entire lifecycle of a product, from concept to disposal. It involves the integration of people, data, processes, and business systems to enable companies to effectively manage their products throughout their lifecycles. PLM encompasses all aspects of a product’s lifecycle, including design, development, manufacturing, distribution, and service.

The goal of PLM is to improve product quality, reduce time-to-market, increase efficiency, and enhance collaboration among different departments and stakeholders. PLM provides a centralized platform for managing product-related data, such as product specifications, engineering drawings, bill of materials, and supplier information. This enables companies to make informed decisions, optimize product design and development, and respond quickly to changing market demands.

Overall, PLM is an essential tool for companies seeking to enhance their product development and management processes and maintain a competitive edge in today’s fast-paced and complex business environment.

Features

A good Product Lifecycle Management (PLM) system should have the following features:

Comprehensive data management: The system should provide a centralised platform for managing all product-related data, including product specifications, engineering drawings, bill of materials, and supplier information.

Collaboration and communication: The PLM system should enable collaboration and communication among different departments and stakeholders involved in the product development and management process.

Workflow management: The system should support workflow management, enabling companies to automate and streamline product development and management processes.

Product data tracking: The system should allow companies to track product-related data throughout the entire product lifecycle, from concept to disposal.

Change management: The PLM system should enable companies to manage product changes effectively, including change requests, approvals, and implementation.

Integration with other systems: The PLM system should integrate with other enterprise systems, such as enterprise resource planning (ERP) and supply chain management (SCM), to streamline processes and reduce data entry errors.

Reporting and analytics: The system should provide reporting and analytics capabilities to enable companies to make informed decisions and optimise product development and management processes.

Regulatory compliance: The PLM system should ensure regulatory compliance by tracking and managing product-related data in accordance with relevant regulations and standards.

Overall, a good PLM system should be flexible, scalable, and customizable to meet the specific needs of each company and enable them to effectively manage their products throughout their lifecycles.