MANUFACTURING MODULE

The Odoo Manufacturing App provides an all-encompassing platform for managing and optimising manufacturing processes. It includes advanced tools for production planning, inventory management, bill of materials (BOM), and quality control. By leveraging real-time data and integration with other Odoo modules, this app enhances operational efficiency, ensures accurate production tracking, and supports continuous improvement, making it an invaluable asset for manufacturers seeking to streamline their operations and achieve higher productivity.

Production Planning

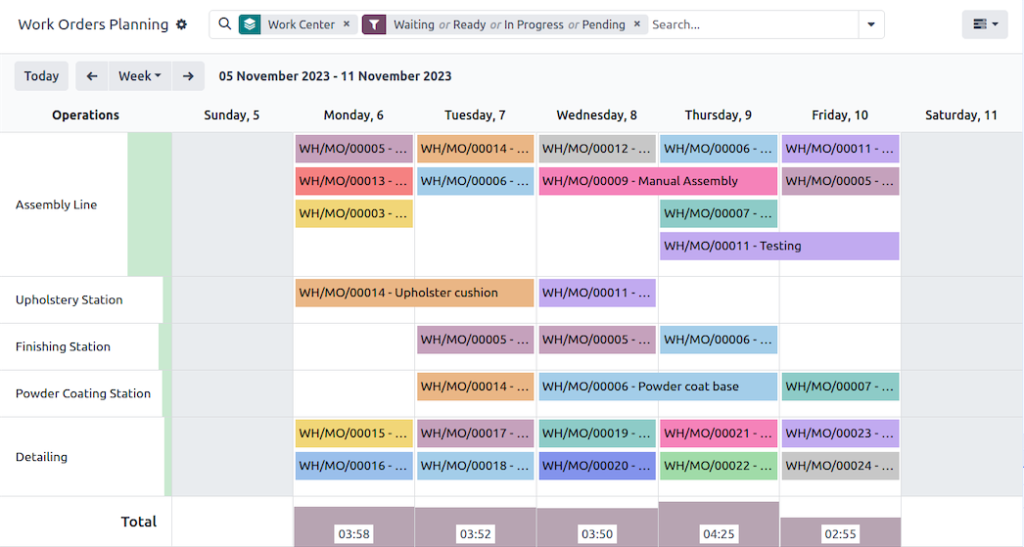

Organise Work Orders: Have access to all available resources and plan ahead with your production.

Plan Manufacturing: Get a clear view on your whole planning and easily reschedule manufacturing.

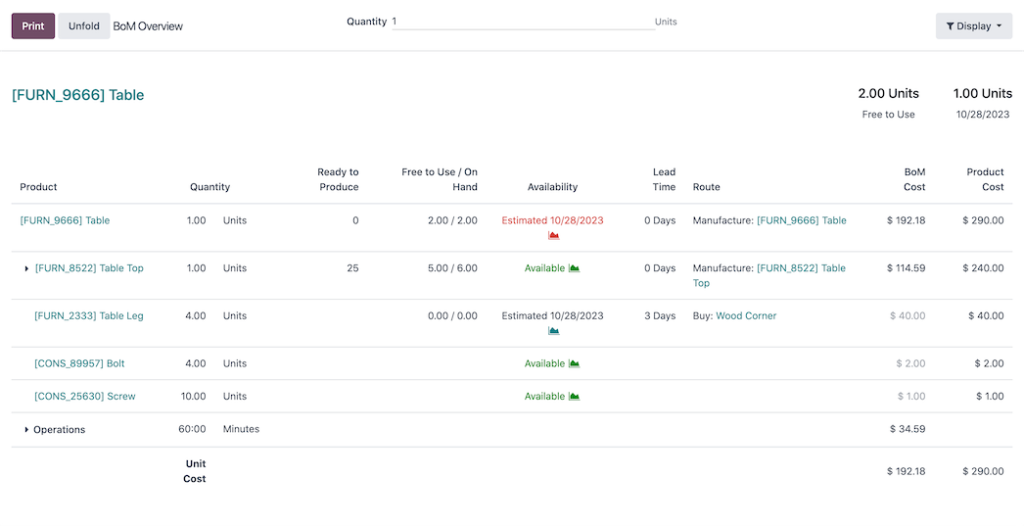

Manage Bill of Materials: Keep track of availability of items in stock and production time.

Workcenter Capacity: Use the MRP Scheduler to schedule your work at each workcenter, based on their OEE and capacity.

Planning that puts you ahead of schedule

Schedule manufacturing orders and plan resources with finite capacity planning.

Fine tune easily with the Gantt chart.

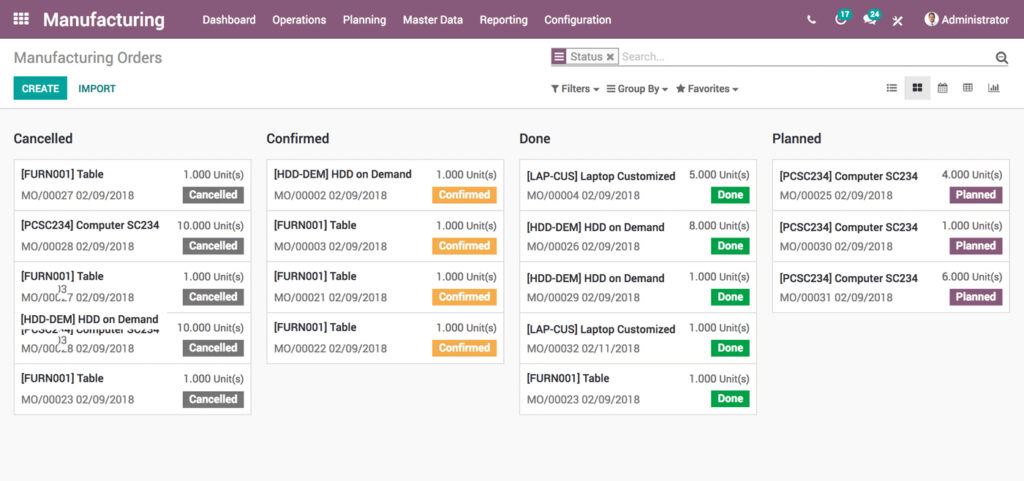

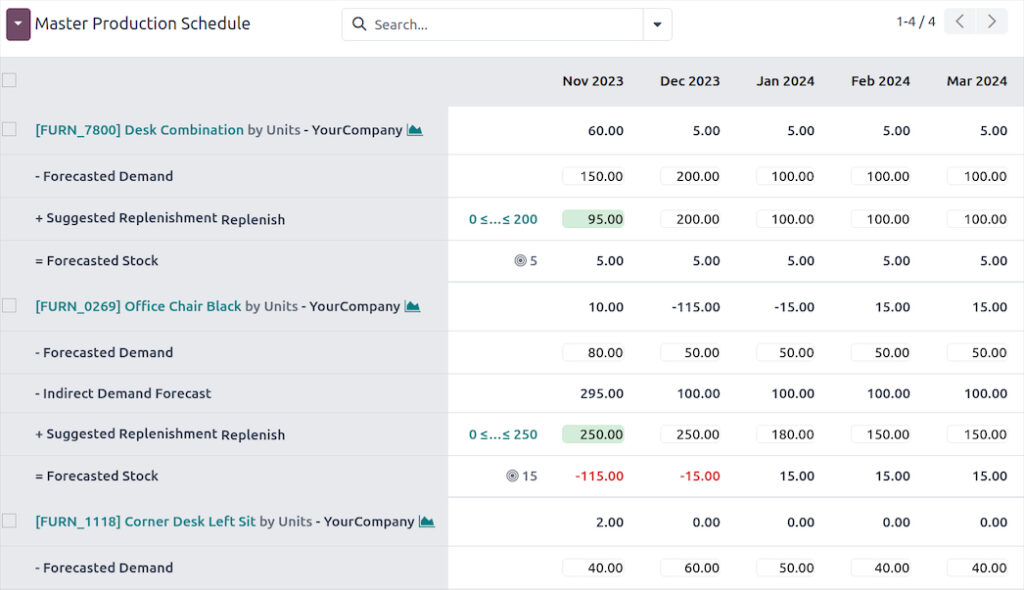

Master production schedule

Manage Bill of Materials: Keep track of availability of items in stock and production time.

Work Orders: Launch production of items needed in the final assembly of your products.

Repair Orders: Manage repairs of items under warranty or as a service.

Unbilled Orders: Disassemble a finished product and recuperate components.

Create Multi-Level Bills of Materials: Set a Bill of Materials within another in order to manufacture components of a product in another Bill of Materials.

Digitised Workflow Processing

The Shop Floor app helps streamline your manufacturing line. Through the tablet-optimised dashboard, you can organise workers, workcenters, worksheets, quality tests, and much more.

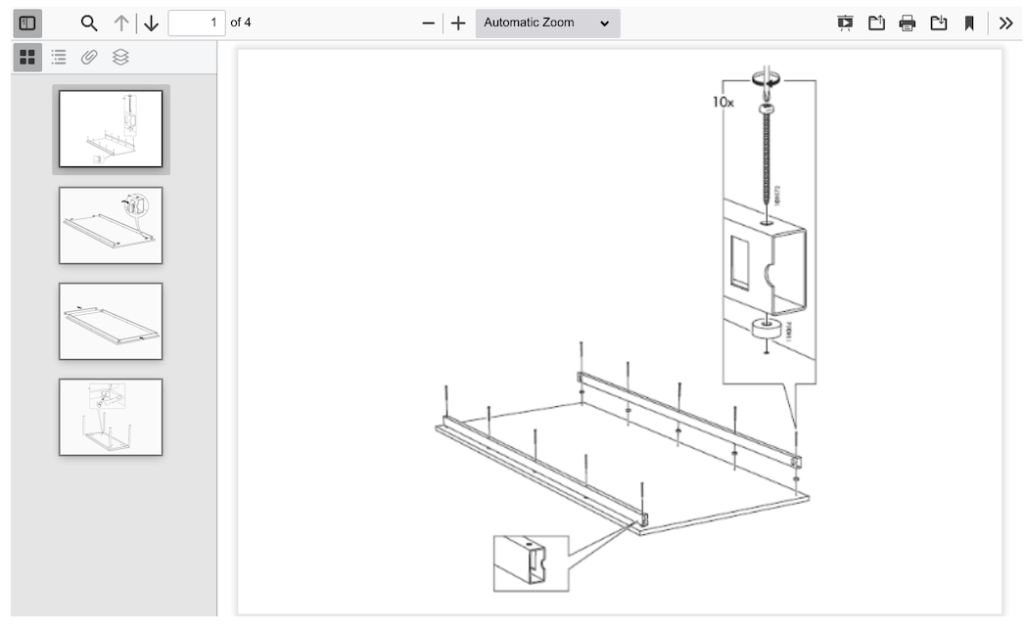

Work Order Steps: Define multiple steps in a work order and link them to worksheet pages: scan a product, take a picture, quality control, etc.

Work Order Steps: Define multiple steps in a work order and link them to worksheet pages: scan a product, take a picture, quality control, etc.

Traceability: Get a full upstream traceability report on the components used during the manufacturing process

Cost Analysis: Track the cost of each manufacturing order based on the cost of the components and on the cost of your operations (labor or material).

Worksheets: Display worksheets directly on the work center with instructions for the operator.

Record Production: Register productions, scan products, lots or serial numbers.

Overall Equipment Effectiveness: Analyse your work centers loads, the productivity losses and track your overall equipment effectiveness (OEE)

Real-time simulated operations

Simulate manufacturing orders with real-time capacity planning, components availability, and cost control.

Get just-in-time replenishment propositions and choose how to fulfill parts: make or buy, sub-contract, or deliver from another warehouse.