INVENTORY & MRP

Features

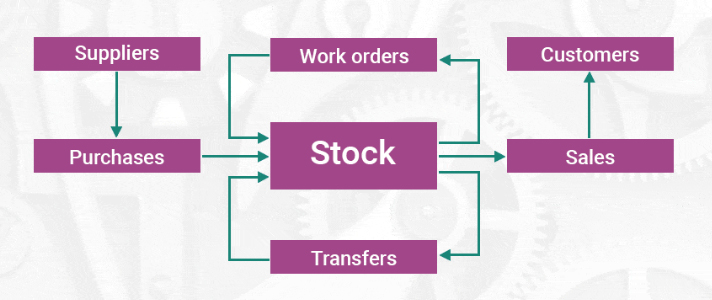

Double Entry Inventory: The unique double entry inventory management allows full traceability from the supplier to the customer. Nothing is lost, everything is moved.

Multiple Locations: Use hierarchical locations to structure your warehouse: zones, rows, shelves, bins, or other locations within your warehouse.

Put Away & Removal Strategies: Define your own storage and removal strategies; fifo, nearest available zone, lifo, or other options.

Multi-Warehouses: Manage all your warehouses with the same system and define replenishment rules between warehouses.

Pick – Pack – Ship: Design your own order process flow. Deliver to customers in one step (delivery order) or several steps: picking, packing, shipping.

Activity Log: Have the history of all operations attached to every document (picking, delivery order, quality control) for full traceability.

Multiple Unit of Measures: The system supports multiple unit of measures and converts automatically for you: buy per tons and sell in kg.

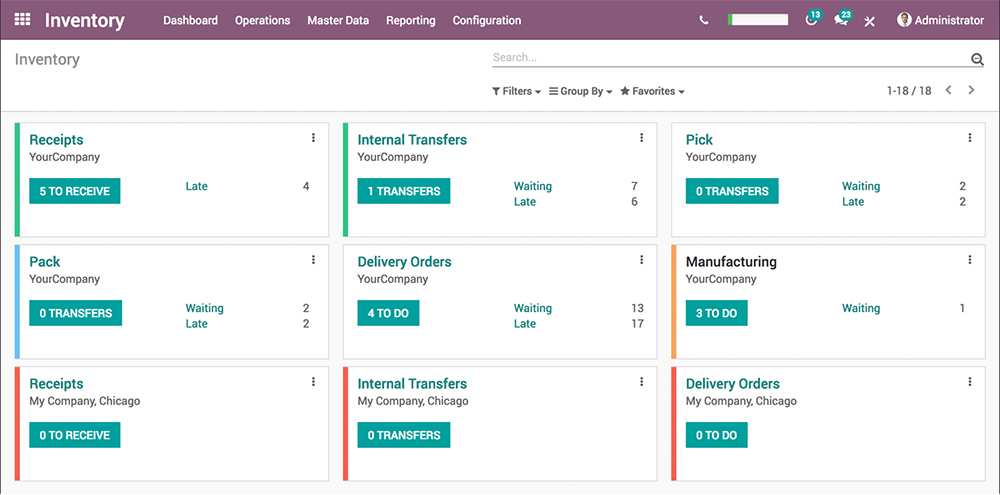

Dashboard: Use predefined dashboards or build your own with the advanced reporting engine. Share filters with the team.

Maximise your Warehouse Efficiency

Modern online warehouse management software.

Improve Performance & Process Time

Better organise your warehouse with the smart double entry inventory system. Get the most efficient stocking method and improve all your internal operations. The double-entry inventory has no stock input, output or transformation. Instead, all operations are stock moves between locations. Less stock, no stockouts with fully automated replenishment. Use order points and automated RFQs to make your supply chain more efficient than ever.

Manufacturing

MRP + Maintenance + PLM + Quality

Inventory

The most efficient stocking method that improves all the internal operations. The double-entry inventory has no stock input, output or transformation. Instead, all operations are stock moves between locations.

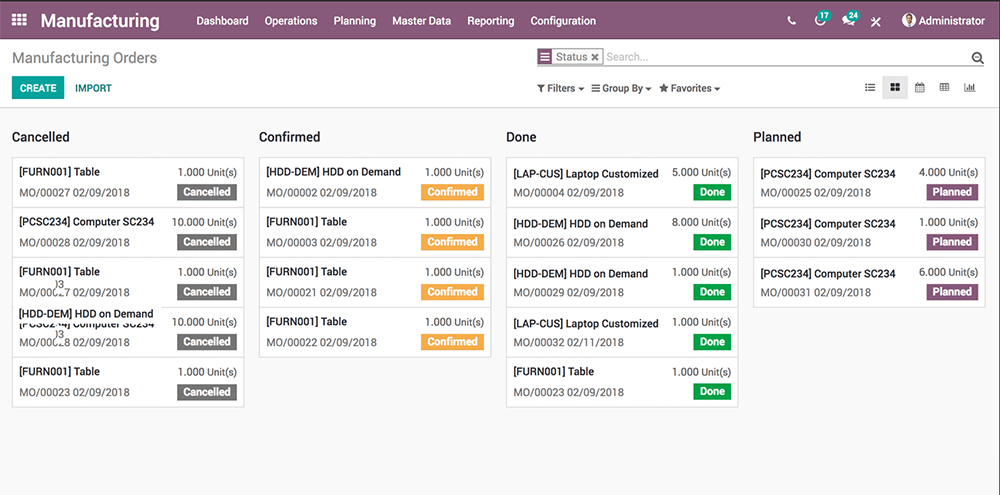

Manufacturing

Manage your products into assembly lines or manual assembly. Launch production of items needed in the final assembly of your products, while you get a clear view on your whole planning to easily reschedule manufacturing.

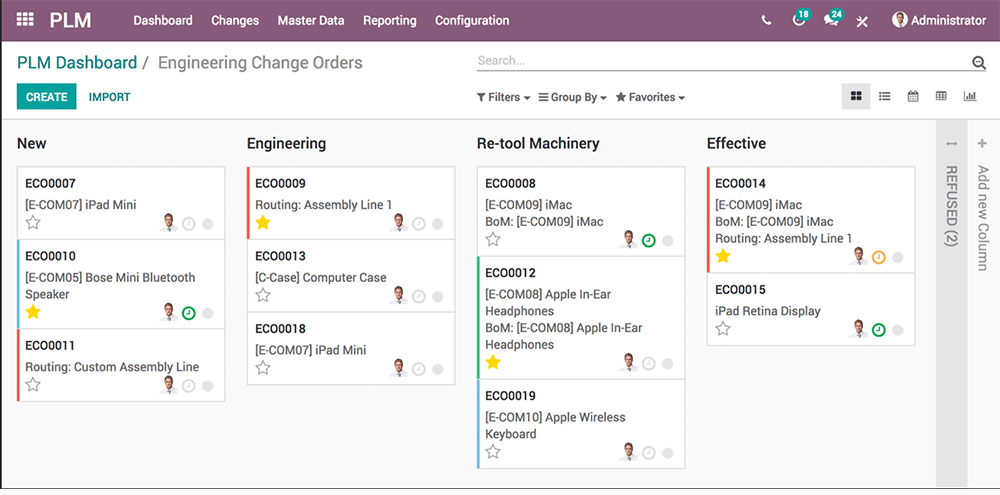

Product Lifecycle Management

Managing engineering changes efficiently is all about communication. PLM harnesses the power of an enterprise social network to help you communicate more efficiently across multiple departments.

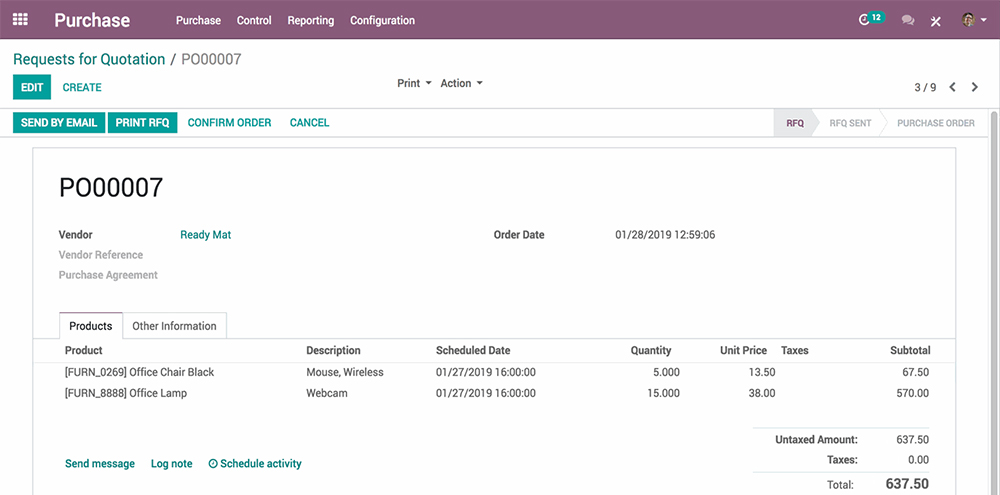

Purchasing

Improve your purchase and inventory performance with procurement rules depending on stock levels, logistic rules, sales orders, forecast manufacturing orders, or other docs. Select different replenishment methods for each product depending on your manufacturing and delivery strategies.

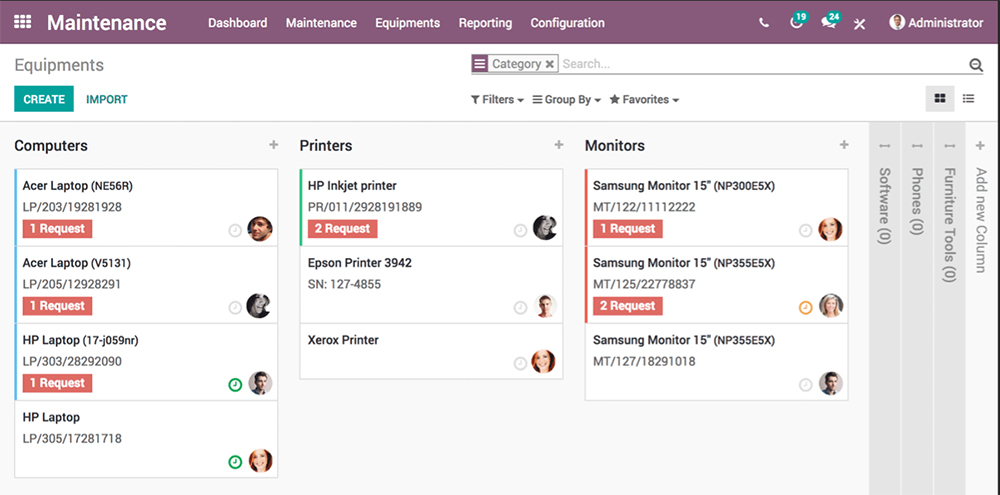

Maintenance

The system computes standard statistics to help you plan preventive maintenance, including mean time between failure (MTBF), mean time to repair (MTTR), and expected next failure date, and lets you automate metrology and preventive maintenance scheduling.

Quality

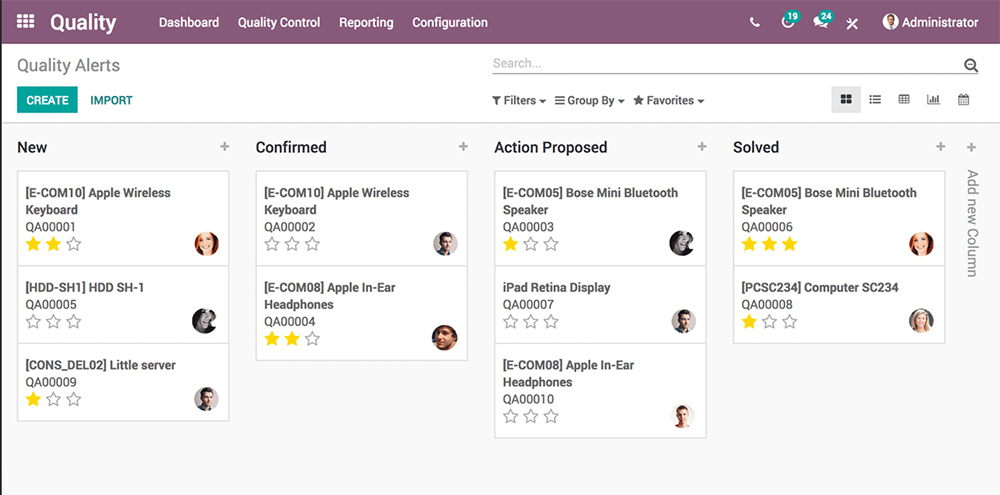

Define quality control plans to trigger quality checks at specific inventory operations (receiving and final inspection) or manufacturing operations (in-process inspection). Drag and drop alerts to report progress and use visual indicators to focus on critical alerts.

Manage Engineering Changes

with real-time communication

Track engineering changes with a great kanban process for ECOs. Everyone follows only what they need, approvals are simple, and discussions on documents are centralised in real time.

- Pass information to manufacturing with triggered alerts on worksheets or work center control panels.

- Attach your documents directly to BoMs, routings or anywhere else.

- Easily manage multiple versions of your documents.

Supplier Price Lists & Product Availability

Make smart purchase decisions using the best prices

Easily import suppliers’ price lists and references to make smarter purchase decisions based on promotions, quantities and special contract conditions. Keep track of a product availability in your supplier’s stock and check your order status from within the app. You can even base your sales price on your supplier’s prices.

Organise your Maintenance Requests

with kanban and calendar views

Easily track the progress of maintenance requests using the kanban view. Use the maintenance calendar to organise and plan activities. Your team will love using the fast and easy drag-and-drop interface to organise maintenance requests.

The manufacturing department can trigger maintenance requests directly from their work center control panel. When your maintenance team acts, the right people will be updated in real time.

Better communication reduces downtime and makes your manufacturing more efficient.

Quality Control Points

Your partner in the APQP journey

Define quality control plans to trigger quality checks at specific inventory operations (receiving and final inspection) or manufacturing operations (in-process inspection).

Set up in-process, final, and receiving inspections based on a quality control plan. Define quality control plans to trigger in-process, final, and receiving inspections.

Manage and track production part approval process (PPAP) submissions. Configure your statistical process control (SPC). Attach process failure mode and effects analysis (PFMEA) documents to routings.

Inventory Module Features

Clean & Fast

Double Entry Inventory: The unique double entry inventory management allows full traceability from the supplier to the customer. Nothing is lost, everything is moved.

Mobile: Scan products in your warehouse using the barcode scanner. Control your dashboards and track orders wherever you are.

Corrected Posted Transactions: You are able to update any transaction (picking, manufacturing order) after being posted through the new lock/unlock button.

Modern User Interface: A fast user interface designed for modern inventory management. Get more work done with less effort with or without barcode scanners.

Flexible: Easily manage a single inventory or a complex multi-warehouses environment by activating features on demand.

Basic Operations

Delivery Orders: Pack orders and deliver with or without barcode scanners. The system prepares delivery orders for you based on availabilities.

Inventory Adjustments: Do an inventory for a zone, a specific product, a lot or a pallet/box; the system prepares cycle counts for you.

Multiple Locations: Use hierarchical locations to structure your warehouse: zones, rows, shelves, etc.

Manufacturing Repairs: Use extra apps to manage manufacturing orders, repairs orders, etc.

Receipts: Control incoming products and compare to what was ordered from the supplier.

Packing: Pack products in just a click and assign barcodes to packs for an easy tracking of the orders.

Scrap Products: Scrap products in just a few clicks and get clear reports on scrap: their costs, reasons and volumes.

Stock Transfers: Use the simple transfer interface to move products from one location to another.